TYPES OF SALT BY ORIGIN OR SOURCE

According to the place of origin of the salt or the state found (as solid mineral deposit or dissolved in seawater) and the way crystallization takes place (harvesting by thermal evaporation of sea salt, mining for the rock salt or thermo compression for vacuum salt) the salt can be classified into different types as follows:

- Sea Salts

- lGourmet Salts

- Gema Salt/Mine

- Salts Briquette

USAGE OF SALT BRIQUETTE

–Salt briquette and salt tablet

- Softening, Water Treatment and swimming pools

- Retail, Hypermarkets, Supermarkets, Cash and Horeca

–Salt Block

- Used in all cattle species as a supplement of the different sea salts. Sea salt block is ideal for using in Biological Farming.

TYPES OF SALTS BRIQUETTE

1.Salt Briquette, are formed from fine dried pure salt which undergoes a mechanical compacting process and depending on the type of molds, different shapes are obtained.

2. Salt Tablet, compressed salt fines into tablets of various kinds of granular materials, in addition to suppress the salt tablet, it can also press various geometries of the special-shaped tablets, double-sided lettering pieces,

3. Salt Block, compacted by mechanical compression process to obtain a compacted block resistant to harsh external conditions.

REQUIREMENT OF SALT CHARACTERISTICS FOR BRIQUETTING

–The size-range

The size-range varies between 0 and 2 mm, according to the available fraction selected by the producer to produce the briquettes. The choice between very fine fractions (below 200-300 µm) can have important consequences on press operating parameters, particularly regarding the method used to feed the moulding rolls. The ideal size-range would combine some coarser crystals to finer particles (< 100 µm) in order to optimize the mix compacity and form a strong briquette.

–The moisture

Its moisture is generally < 0.2 %. Salt is very often fed hot to the briquetting press (40-60°C) and this helps briquetting allowing a better combination of crystals. Salt can also be briquetted cold but this does require a higher pressure level.

SALT BRIQUETTING MACHINE

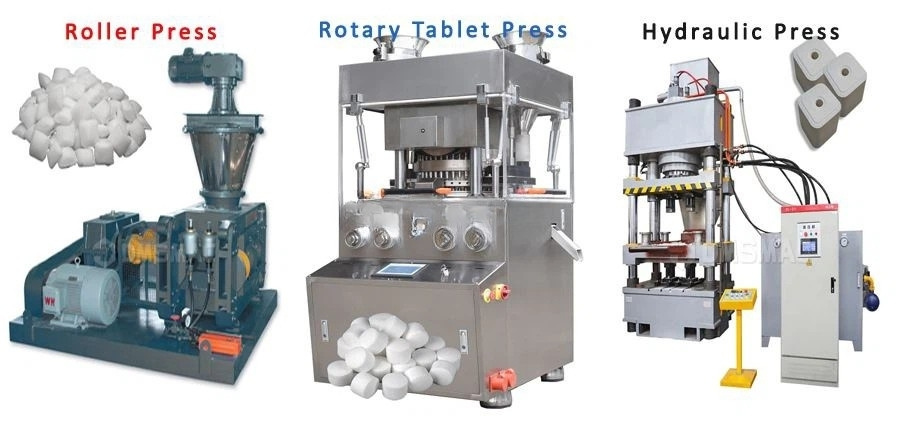

Use three different types of machine depending on the shape and size of the salt briquette you need: