Mixer System

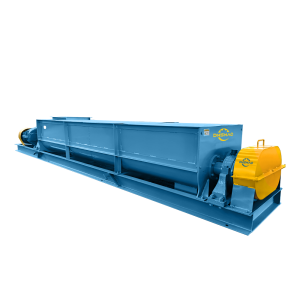

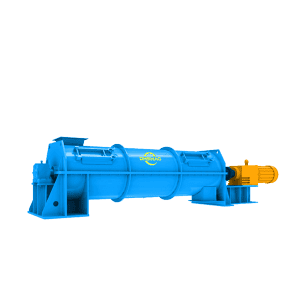

DMSMAC provides a variety of mixing equipment for different material characteristics to meet the needs of customized production lines. The advantages of double shaft forced mixers are strong power and quantitative and timed uniform mixing, which is suitable for batch materials with strict ratio requirements; the double-shaft mixer achieves continuous mixing of different materials through the double-shaft mixing blade design, which is suitable for continuous large-scale production; the ribbon mixer has a reverse double-ribbon structure with paddle blades, and the mixing ratio is accurate and uniform, which is suitable for batch production with light specific gravity and high mixing uniformity requirements; the wheel wheel mixer (also known as the planetary mixer) adopts multiple repeated tossing and rolling mixing, which is suitable for uniform batch production of viscous materials with light specific gravity and poor water absorption. According to the characteristics of the customer’s raw materials, different mixing equipment can be selected, which can be selected alone or in combination.

Mixer System

Product Categories

Briquette Production Line

Roller Briquette Machine

Dryer system

Heat Source System

Mixer System

Crusher System

Auxiliary Equipment

Recommended Cases

The Briquettes Adhesive Secret, You Don’t Know

The adhesive, there are m

Influence Of Pretreatment Process Of Ball Press Binder

Influence of pretreatment

5 tons per hour fluorite powder briquette press production line

5 tons per hour fluorite

20 Tph Coal Briquettes Plant In Heibei Province

Raw Materials : coal Mois

FAQ's

Frequently Asked Questions

What products does your manufacturing company produce?

We provide a wide range of machinery, including briquette machines, mixers, dryers, and more, designed for various industrial applications.

What is the typical lead time for product delivery?

Lead times vary depending on the machine and customization options. Please contact us for specific timelines related to your order.

What materials can your briquette machines process?

Our briquette machines can process a variety of materials, including biomass, charcoal, and other organic waste products.

What are the energy requirements for your machines?

Each machine has specific energy requirements, which can be provided upon request. We aim to design energy-efficient solutions.