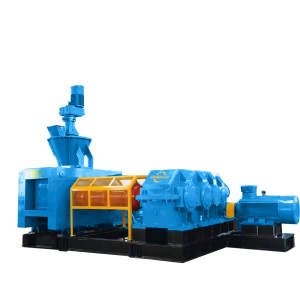

Roller Briquette Machine

Roll Briquetting Machine is a general term for all roller forming equipment, also called granulator. Roller Briquetting Machine has different names according to the standards of different manufacturers. For example, according to the press power of the pressure provided, there are high-pressure briquette machine, medium-pressure briquette machine, etc.; There are also briquetting machine named according to the specific use of the material, such as coal briquetting machine, lime lime briquetting press, iron oxide briquette press machine, fluorite powder briquette press machine, coke briquetting machine, etc.; According to the number of output shafts equipped with the reduction gear, it can be divided into: single-output briquette machine and double-output briquette machine; Here we distinguish according to whether adhesives are added and the application scenarios: Briquetting Machine with Adhesives and Briquetting Machine without Adhesives, as well as Multi-functional Lab Briquetting Machine for laboratories, and Special-Purpose Custom-made Briquetting Machine; No matter which way the name is used, it will not change the design and function of the briquetting press. For detailed design, please check the specific page.

Regarding which type of roller briquetting machine to choose, please consult the engineer to understand the specific application process requirements. For detailed design, please check the specific page.

Roller Briquette Machine

Product Categories

Briquette Production Line

Roller Briquette Machine

Dryer system

Heat Source System

Mixer System

Crusher System

Auxiliary Equipment

Recommended Cases

The Briquettes Adhesive Secret, You Don’t Know

The adhesive, there are m

Influence Of Pretreatment Process Of Ball Press Binder

Influence of pretreatment

5 tons per hour fluorite powder briquette press production line

5 tons per hour fluorite

20 Tph Coal Briquettes Plant In Heibei Province

Raw Materials : coal Mois

FAQ's

Frequently Asked Questions

What products does your manufacturing company produce?

We provide a wide range of machinery, including briquette machines, mixers, dryers, and more, designed for various industrial applications.

What is the typical lead time for product delivery?

Lead times vary depending on the machine and customization options. Please contact us for specific timelines related to your order.

What materials can your briquette machines process?

Our briquette machines can process a variety of materials, including biomass, charcoal, and other organic waste products.

What are the energy requirements for your machines?

Each machine has specific energy requirements, which can be provided upon request. We aim to design energy-efficient solutions.