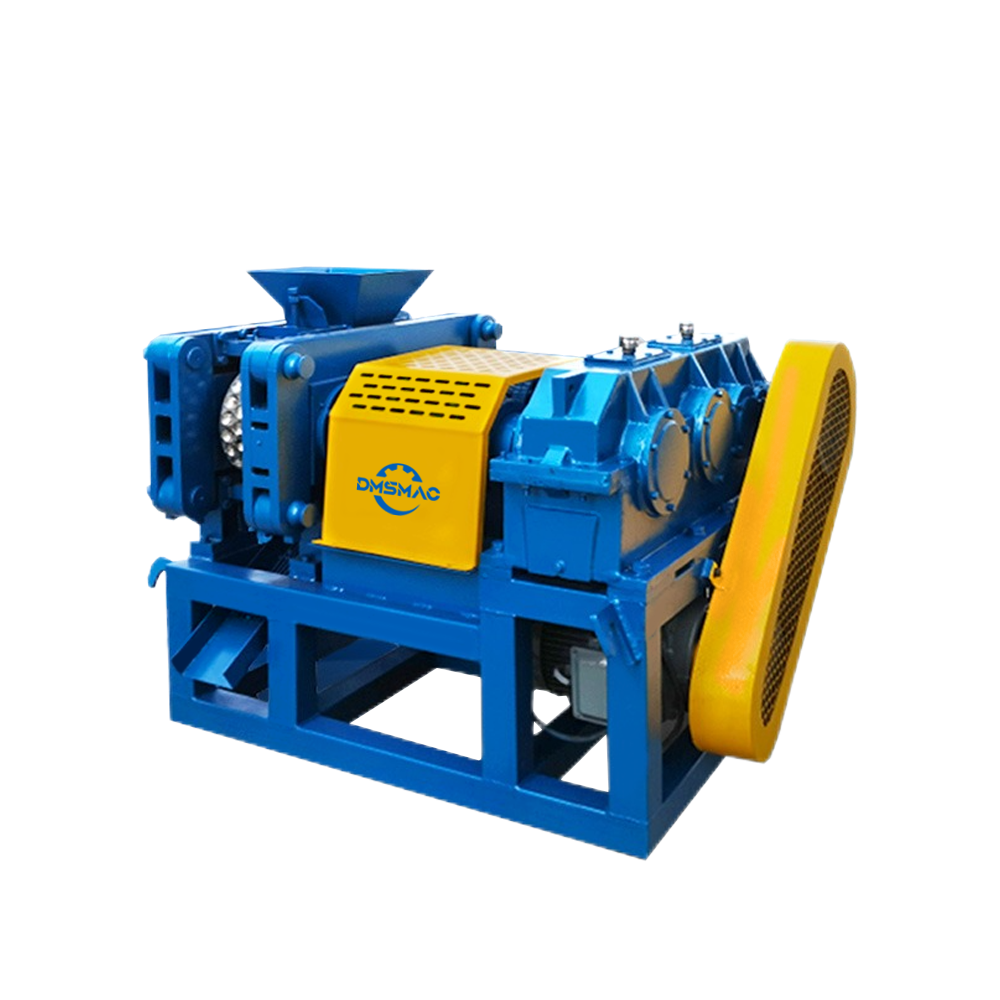

Briquetting Machine With Adhesive

Advantages:

Production: 100-50000 kg/hour;

Application range; All raw materials that require adhesive to assist in forming, such as anthracite, lignite, coal slime, charcoal slag, carbon black, iron oxide, fluorite powder, etc.;

Shape and size of finished briquettes; Round, oval, pillow, heart-shaped and other special customized shapes, from 15 mm to 80 mm;

Features:

- Safe, stable and reliable operation: While the hydraulic device provides active pressure, the overload protection effectively protects the roller from being damaged by foreign objects; the control cabinet effectively protects the main motor, and is equipped with an overload protection device and a short-circuit protection device; the pin coupling effectively protects the main shaft from being damaged under overload and fault conditions;

- Convenient and quick operation: Start the main machine with one button and it can be put into operation, reducing installation and debugging time; the ball socket adjustment device is simple and easy to operate to ensure the high quality of the finished ball; the roller sleeve and core design are easy and convenient to replace at a low cost.

- Lower cost of use: customized high chromium alloy roller material, long service life, warranty of 30,000 tons, low replacement cost; finished ball has high strength, high quality, low return ratio, and higher cost performance; solid frame beam structure, national standard plate, more solid structure, single machine weight is 20%-30% heavier than peers; famous brand motor reducer, and bearings: provide sufficient power and effective transmission, run more smoothly, and no noise;

- PDF DOWNLOAD

1. What is Briquetting machine with adhesive?

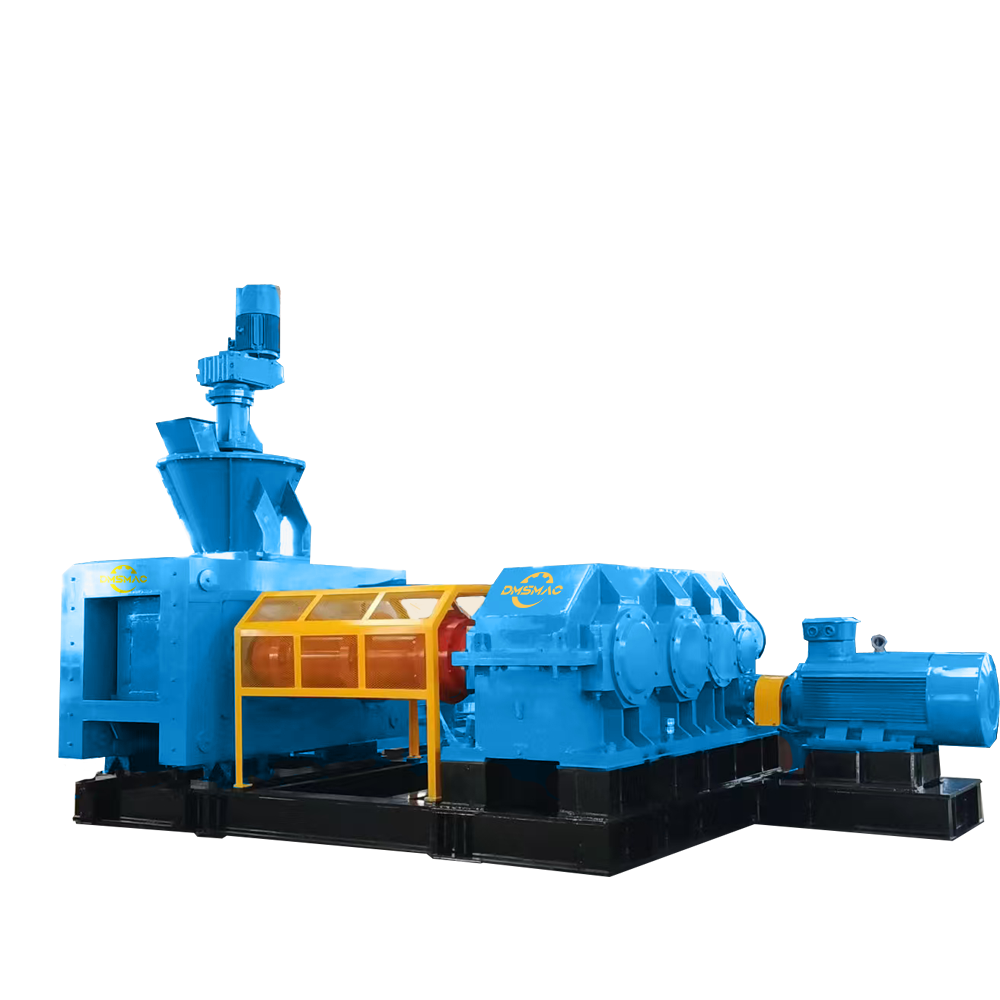

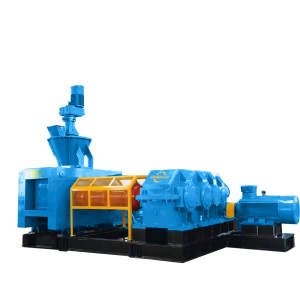

Briquetting machine with adhesive refers specifically to a device that squeezes powdered materials mixed with adhesives into briquettes through rollers at room temperature. It is mainly used in briquettes pressing equipment in production processes that require adhesive assistance; according to customer raw materials and process requirements, different configurations of Briquetting machine with adhesive are selected, usually with crushers, mixers, drying equipment and conveyor device.

2. What is the working principle of briquetting machine with adhesive?

The raw materials mixed with the adhesive are conveyed to the hopper of the briquetting press through the conveying device. The mixture is evenly distributed between the two rollers through the hopper under the action of gravity. As the motor drives the reducer to drive the rollers to rotate synchronously in the opposite direction through the synchronous reverse gear, the pressure on the material in the middle of the rollers increases from top to bottom. When the material rotates to the line contact point of the two rollers, the pressure on the material reaches the peak. Under the action of the huge line pressure, the gap between the mixture is compressed to the minimum, and the mixture changes from powder to finished briquettes. As the molding wheel rotates, the briquettes socket gradually separates, and the molding pressure decreases rapidly. The pressed materials begins to expand and detach, and is transported to the next level of conveying device through the belt conveyor to complete the briquettes pressing process.

3. What are the mechanical structures and functions of the briquetting machine with adhesive:

Motor: Provides power and transmits power through belts and pulleys;

Reducer: Transmits the power of the motor through pulleys or couplings, and reduces the motor speed to the speed required by the host;

Coupling: Connects the reducer and the main shaft to transmit power from the motor. The pin coupling can also provide overload protection;

Pressing roller assembly: roller, main shaft, bearing and bearing seat, synchronous reverse gear.

Main frame beam: fixes the main shaft and bearing seat and provides support;

Hydraulic system: provides active pressure between the rollers to protect the rollers;

Electronic control system: controls and protects the start and stop of the motor;

Discharging system: The finished balls are transported from under the rollers to the next level of belts.

4. Application fields of briquetting machine with adhesive:

The molding process can not only reduce dust and control bulk density, but also improve the utilization rate of waste materials, with good economic and social benefits;

After the coal powder mixed with specific adhesives is molded, the physical and chemical indicators have been significantly improved compared with the original coal blocks, such as high cold and hot strength and enhanced water resistance;

At the same time, a variety of different raw materials can be mixed according to process needs, and the physical and chemical indicators of the finished product can be artificially adjusted to reduce the ash content and the content of harmful substances to make its use more extensive and economic value higher.

For the above reasons, briquette machines are widely used in: refractory industry, thermal power plants, metallurgy, chemical industry, energy, transportation, heating, etc.

The specially designed and improved briquette machines can be widely used in: iron powder briquette, coke briquette, aluminum powder briquette, iron filings briquette, iron oxide briquette, carbon powder briquette, slag briquette, gypsum briquette, tailings briquette, sludge briquette, kaolin briquette, activated carbon briquette, coke powder and other powder briquette, waste slag pressing molding, etc

5. What are the technical parameters of the briquetting machine with adhesive?

| Model | ZY290 | ZY360 | ZY450 | ZY500 | ZY600 | ZY650 | ZY750 | ZY800 | ZY850 | ZY1000 | ZY1200 | ||

| Capacity(t/h) | Charcoal | 0.5-1 | 1-2 | 1.5-2.5 | 2-3 | 3-5 | 4-6 | 6-7 | 8-10 | 10-12 | 15-18 | 20-30 | |

| Coal | 2-3 | 3-5 | 4-6 | 5-7 | 8-10 | 10-12 | 13-15 | 18-20 | 20-25 | 30-40 | 50-70 | ||

| Mineral Power | 4-6 | 6-8 | 8-10 | 10-12 | 15-18 | 18-20 | 22-25 | 30-35 | 35-40 | 40-60 | 80-100 | ||

| Roller width(mm) | 200 | 250 | 250 | 300 | 350 | 350 | 400 | 500 | 500 | 700 | 1000 | ||

| Roller diameter(mm) | 290 | 360 | 450 | 500 | 600 | 650 | 750 | 800 | 850 | 1000 | 1200 | ||

| Power | kW | 5.5-7.5 | 7.5-11 | 11-15 | 18.5-22 | 30-37 | 37-45 | 45-55 | 55-75 | 75-90 | 90-132 | 160-185 | |

| Hp | |||||||||||||

| Reducer | ZQ350 | ZQ400 | ZQ400 | ZQ500 | ZQ650 | ZQ750 | ZQ750 | ZQ850 | ZQ1000 | ZSY500 | ZSY560 | ||

| Pressure type | Mechanical/Hydraulic System | Hydraulic System | |||||||||||

| Roller speed(rpm.) | 20 | 18 | 15 | 13 | 13 | 13 | 12 | 12 | 10 | 10 | 9 | ||

| Roller material | 9Cr2Mo/9Cr18/65Mn | ||||||||||||

| Hardness of roller | HRC58-60 | ||||||||||||

| Feeding method | Gravity/Force Feeding | ||||||||||||

| Rated line pressure(t/cm) | 2-3 | 2-3 | 2-3 | 2-3 | 3-5 | 3-5 | 3-5 | 3-5 | 4-6 | 6-8 | 8-10 | ||

| Note: The above configuration can be adjusted according to user needs. | |||||||||||||

6. What are the characteristics and advantages of the DMSMAC briquetting machine with adhesive?

1. Lower cost of use:

1-1: The finished briquettes has high strength, high quality, low return ratio, and higher cost performance;

1-2: The frame beam structure is more solid, with lifetime warranty: solid steel beam, national standard plate, and the weight of a single machine is 20% heavier than its peers;

1-3: Famous brand motor reducer, and bearings: provide sufficient power and effective transmission, run more smoothly, and no noise;

1-4: Customized roller material, long service life, low replacement cost;

2. Safe and reliable operation:

2-1: The hydraulic device provides active pressure At the same time, the overload protection effectively protects the roller from being damaged by foreign objects;

2-2: The control cabinet effectively protects the main motor, and is equipped with an overload protection device and a short circuit protection device;

2-3: The pin coupling effectively protects the main shaft from being damaged under overload and fault conditions;

3. Convenient and quick operation:

3-1: Start the main machine with one button and it can be put into operation, reducing installation and debugging time;

3-2: The briquettes socket device is simple and easy to operate to ensure the high quality of the finished briquettes;

3-3: The roller sleeve and core design are easy and convenient to replace with low cost.

FAQ's

Frequently Asked Questions

What products does your manufacturing company produce?

We provide a wide range of machinery, including briquette machines, mixers, dryers, and more, designed for various industrial applications.

What is the typical lead time for product delivery?

Lead times vary depending on the machine and customization options. Please contact us for specific timelines related to your order.

What materials can your briquette machines process?

Our briquette machines can process a variety of materials, including biomass, charcoal, and other organic waste products.

What are the energy requirements for your machines?

Each machine has specific energy requirements, which can be provided upon request. We aim to design energy-efficient solutions.

Request A Quote

Briquetting Machine With Adhesive

Advantages:

Production: 100-50000 kg/hour;

Application range; All raw materials that require adhesive to assist in forming, such as anthracite, lignite, coal slime, charcoal slag, carbon black, iron oxide, fluorite powder, etc.;

Shape and size of finished briquettes; Round, oval, pillow, heart-shaped and other special customized shapes, from 15 mm to 80 mm;

Features:

- Safe, stable and reliable operation: While the hydraulic device provides active pressure, the overload protection effectively protects the roller from being damaged by foreign objects; the control cabinet effectively protects the main motor, and is equipped with an overload protection device and a short-circuit protection device; the pin coupling effectively protects the main shaft from being damaged under overload and fault conditions;

- Convenient and quick operation: Start the main machine with one button and it can be put into operation, reducing installation and debugging time; the ball socket adjustment device is simple and easy to operate to ensure the high quality of the finished ball; the roller sleeve and core design are easy and convenient to replace at a low cost.

- Lower cost of use: customized high chromium alloy roller material, long service life, warranty of 30,000 tons, low replacement cost; finished ball has high strength, high quality, low return ratio, and higher cost performance; solid frame beam structure, national standard plate, more solid structure, single machine weight is 20%-30% heavier than peers; famous brand motor reducer, and bearings: provide sufficient power and effective transmission, run more smoothly, and no noise;

- PDF DOWNLOAD

▶Product Advantage:

—Hydraulic System Option

—Horizontal and Vertical Feed for Screw or Gravity Feed Options

—Pocket Adjustment Design to Make Sure Getting Beautiful Final Briquettes

—Customized Sizes and Shapes for Briquettes

—Variable Speed Roll and Screw Feeder Drives to Maximize Product Quality

—Rolls and Feed Screws Available In Wear and Corrosion-Resistant Alloys

—Designed For Easy Maintenance

—Solid Oil Filled Bearings Option

▶Working Principle:

The material to be briquetted is introduced into the space above two counter-rotating rollers via feeder system. On passing through the roller gap, the material is compacted and formed into briquettes of uniform size and shape. For briquetting at feed material , it may be necessary to add binders to improve the briquette-forming characteristics.

▶Technical Parameters:

▶Engineering Case:

Roller Briquette Machine

- — Briquetting Machine

- — High Pressure Briquette Machine

Biomass Briquette Machine

Briquette Plant

Dryer system

Charcoal Making Machine

- — Rotary Type Charcoal Machine

- — Batch Type Charcoal Making Machine