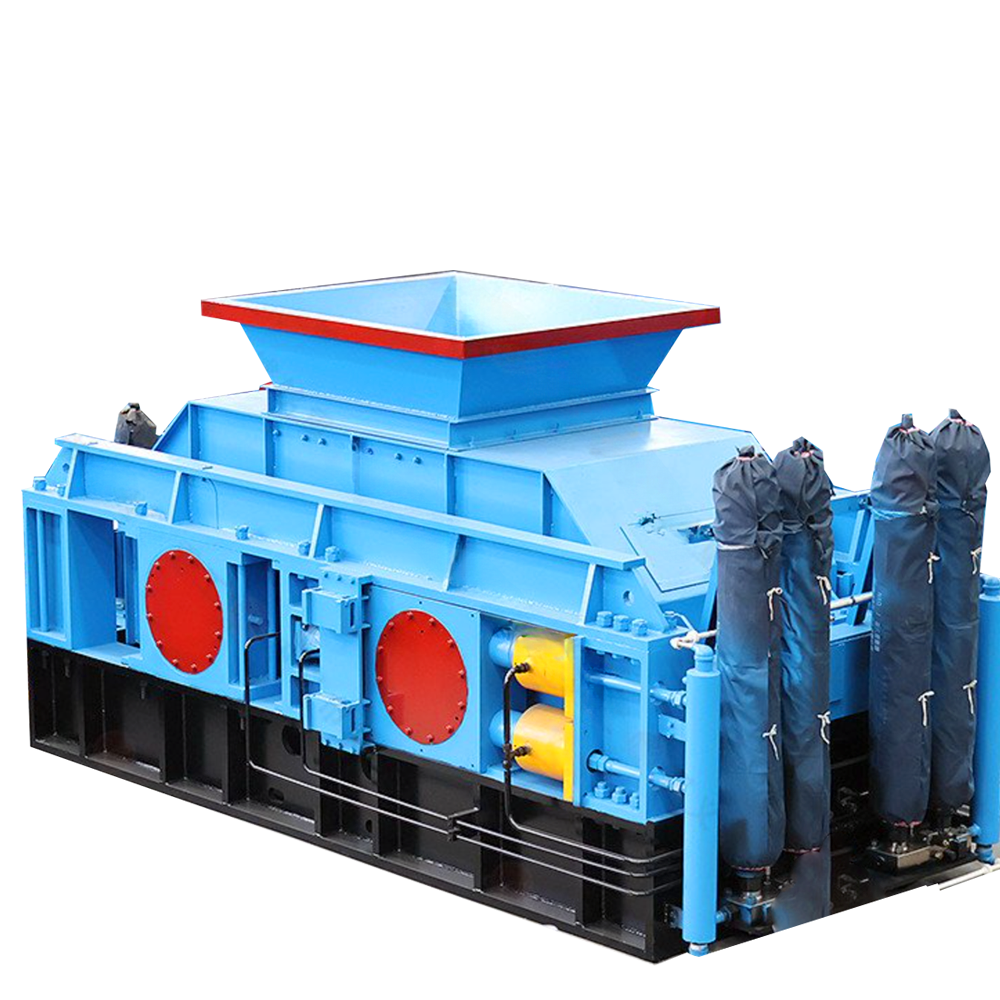

Hammer Blade Crusher

Output: 0.5-15 tons/hour

Application range: Mainly used in the crushing of feed raw materials such as grains, biomass, charcoal slag, bentonite, quicklime and fine and ultrafine powder processes of some soft materials. The finished product particle size can be controlled ≤1mm, such as biomass pellet production line, charcoal ball production line, hookah carbon production line, etc.;

Features:

- The finished product particle size is controllable, the crushing ratio is as high as 50, the finished product rate is high, and the minimum particle size of ≤1mm reaches 95%;

- Tungsten carbide hammer head, wear-resistant, long life;

- Strong power, energy-saving and efficient: the motor is directly connected to the rotor, the speed is high, and the power output is direct;

- No dust, no pollution: used in conjunction with cyclone dust removal and bag pulse dust removal;

- Maintenance and maintenance, simple operation: replace the hammer head and screen, the feed inlet and the motor rotation direction are realized by one device;

- PDF DOWNLOAD

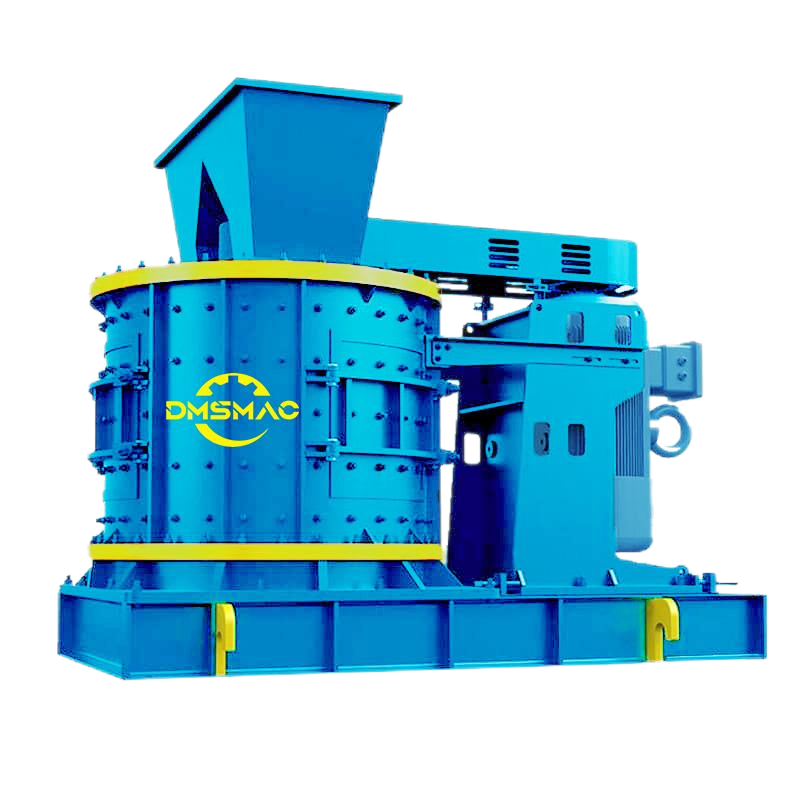

What is Hammer Blade Crusher?

Hammer Blade Crusher, named teardrop-shaped mill or hammer mill also, is a hammer-type(not bigger size hammer but hammer like knife) grinding device designed with a teardrop-shaped crushing chamber as the core. It can adopt a direct-drive structure, optional self-iron removal device and high-quality high-speed bearings, and achieve coarse, fine and micro-fine three-level crushing by adjusting the hammer-screen gap and the screen size. Its core components include a high-speed rotor (speed 2950r/min), optional screen hole size, and can be matched with spiral discharging, wind discharging, and the finished product particle size is controllable and optional.

How does the Hammer Blade Crusher work?

Impact crushing: After the material enters the crushing chamber evenly through the feeding device, it is subjected to the strong shearing and impact of the high-speed rotating hammer to complete the initial crushing;

Self-friction refinement: The material and the screen plate, and the material are further crushed by mutual friction. Particles smaller than the screen hole are discharged through the screen plate, and large particles continue to be circulated and crushed;

Particle Size Control: The discharge fineness is controlled by adjusting the hammer-screen gap (for example, 0.5-12mm) or replacing the screen (for example: aperture 1-12mm), and the forward and reverse rotors are supported to extend the life of the hammer;

What are the core advantages of the Hammer Blade Crusher?

High efficiency and energy saving: the crushing efficiency is 30%-50% higher than that of traditional equipment, and the unit energy consumption is reduced by 20%;

Multi-stage crushing: supports coarse crushing (≤5mm), fine crushing (≤3mm) and micro-fine crushing (≤1mm), and is suitable for feed, chemical, pharmaceutical and other fields;

Simple and fast maintenance: the quick-start door opening mechanism and elastic screen pressing design simplify the replacement of screen plates, and the spring tensioning bracket is adapted to the non-welded screen plate, which improves the maintenance efficiency by 50%;

No dust, no blockage: the closed structure is combined with the spiral unloading and dust removal device to achieve dust-free emission while increasing work efficiency;

What fields are Hammer Blade Crusher used in?

Feed processing: crushing of raw materials such as grains and biomass, and the uniformity of particle size improves mixing efficiency;

Environmental building materials: recycling of solid waste such as charcoal slag and some soft materials, the crushing particle size can be adjusted to ≤1mm;

Industrial raw materials: fine grinding of chemical materials such as bentonite and dolomite to meet the demand for ultrafine powder in the pharmaceutical and ceramic industries.

FAQ's

Frequently Asked Questions

What products does your manufacturing company produce?

We provide a wide range of machinery, including briquette machines, mixers, dryers, and more, designed for various industrial applications.

What is the typical lead time for product delivery?

Lead times vary depending on the machine and customization options. Please contact us for specific timelines related to your order.

What materials can your briquette machines process?

Our briquette machines can process a variety of materials, including biomass, charcoal, and other organic waste products.

What are the energy requirements for your machines?

Each machine has specific energy requirements, which can be provided upon request. We aim to design energy-efficient solutions.

Request A Quote

Hammer Blade Crusher

Output: 0.5-15 tons/hour

Application range: Mainly used in the crushing of feed raw materials such as grains, biomass, charcoal slag, bentonite, quicklime and fine and ultrafine powder processes of some soft materials. The finished product particle size can be controlled ≤1mm, such as biomass pellet production line, charcoal ball production line, hookah carbon production line, etc.;

Features:

- The finished product particle size is controllable, the crushing ratio is as high as 50, the finished product rate is high, and the minimum particle size of ≤1mm reaches 95%;

- Tungsten carbide hammer head, wear-resistant, long life;

- Strong power, energy-saving and efficient: the motor is directly connected to the rotor, the speed is high, and the power output is direct;

- No dust, no pollution: used in conjunction with cyclone dust removal and bag pulse dust removal;

- Maintenance and maintenance, simple operation: replace the hammer head and screen, the feed inlet and the motor rotation direction are realized by one device;

- PDF DOWNLOAD