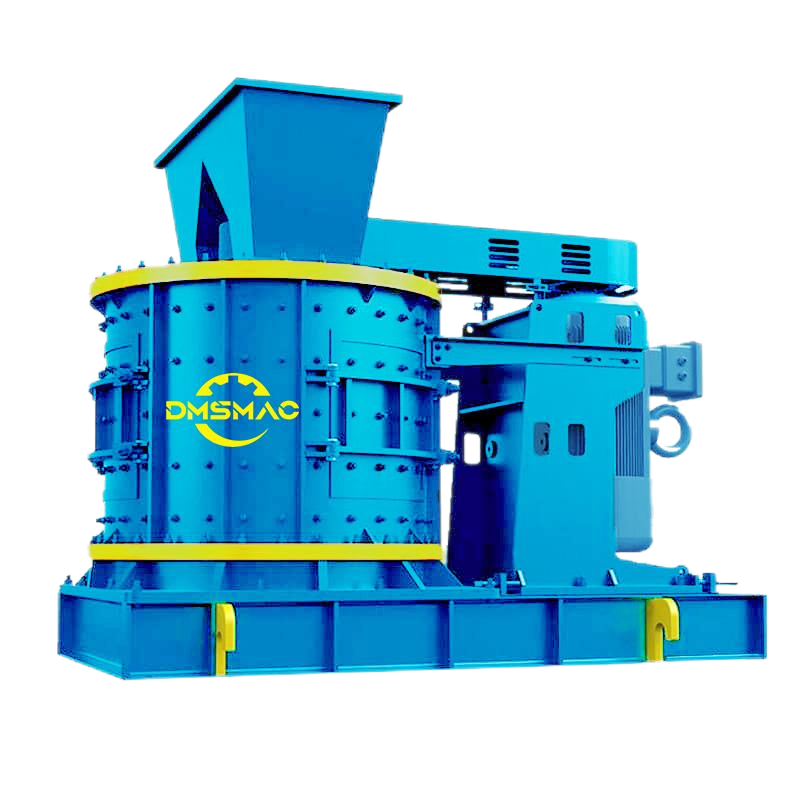

Roller Crusher

Processing capacity: 1-50 tons/hour

Application: Suitable for continuous processing of medium and high hardness materials with compressive strength ≤160MPa, such as coal gangue, anthracite, charcoal slag, river pebbles, granite, etc.; widely used in raw material processing processes in sand and gravel aggregate production lines, briquette production lines, and charcoal ball production lines.

Features:

- Adjustable finished product particle size: adjustable range of discharging particle size 0.5-40mm;

- Strong adaptability, suitable for coal gangue containing moisture, charcoal slag crushing process;

- No screen bottom structure, no material blockage, suitable for long-term continuous production and processing technology;

- Long life, core wear-resistant roller, roller skin hardness reaches HRC60 or above, maintenance cycle up to several years;

- Less dust, no pollution: low crushing noise, less dust, environmentally friendly and clean.

- PDF DOWNLOAD

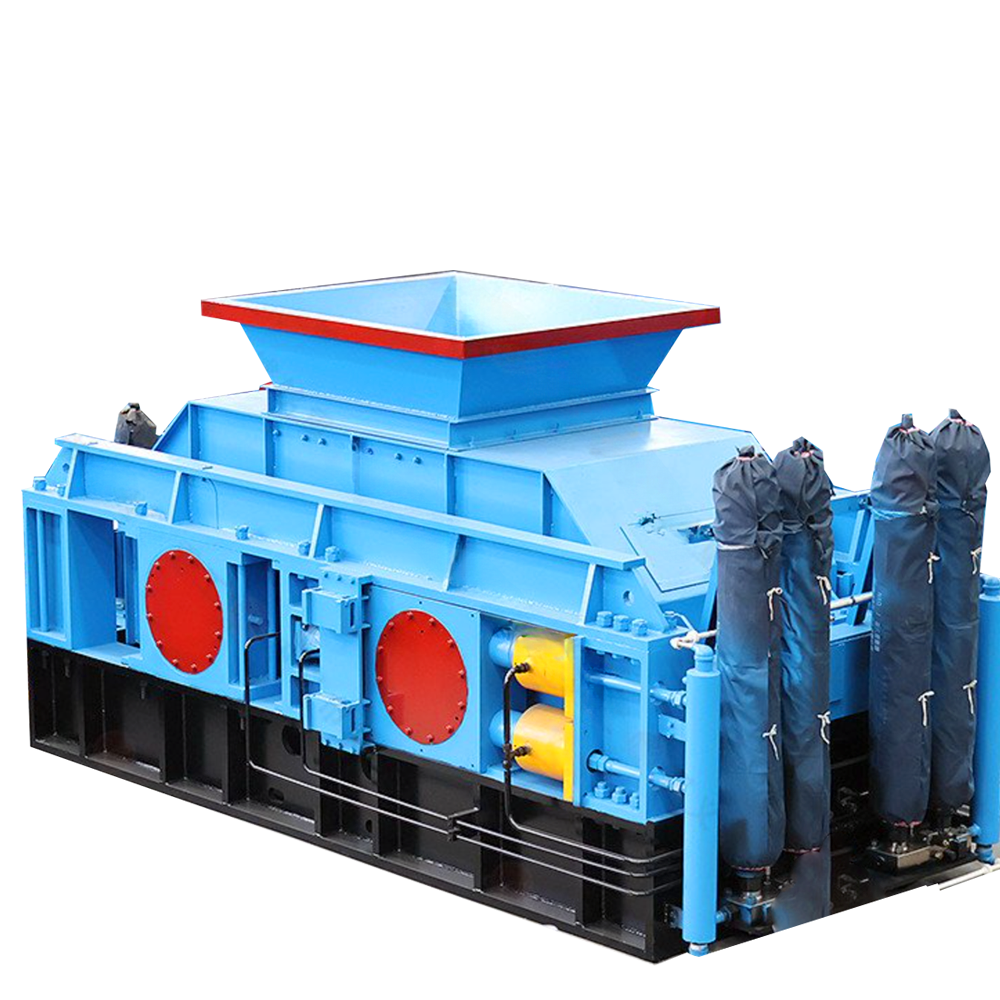

What is roller crusher/tooth roller crusher?

The double-roll crusher (also known as a double-roll crusher, or tooth roller crusher) is a medium-fine crushing device that achieves material extrusion and crushing through two parallel rollers rotating in opposite directions. Its core structure consists of high-strength wear-resistant rollers (manganese steel/alloy steel), hydraulic or spring adjustment devices, drive systems and sealed protective covers. It is suitable for processing medium- and high-hardness materials with a compressive strength of ≤160MPa (such as river pebbles, granite, coal gangue, etc.). The equipment has the characteristics of compact structure, controllable discharge particle size, and low maintenance cost. It is widely used in mining, building materials, metallurgy and environmental protection, as well as briquette and charcoal slag briquette fields.

What is the working principle of the double-roll crusher?

Feeding stage: the material enters the gap between the two rollers evenly through the vibrating feeder (the spacing is adjustable);

Crushing stage: the two rollers rotate in opposite directions (speed 50-300r/min), and the material is crushed by the triple forces of extrusion, shearing and grinding; the roller surface design (tooth shape/smooth surface) enhances the adaptability to different materials;

Discharging stage: the crushed particles are discharged from the bottom, and some models are equipped with screening devices to achieve particle size classification. The hydraulic system adjusts the discharge particle size in real time to ensure that the qualified rate of finished products is ≥90%.

What are the core functions of the double-roll crusher?

Efficient crushing: double-roll extrusion and shearing work together, the crushing ratio reaches 3:1 to 8:1, and the discharge particle size is adjustable (0.5-40mm).

Supports multi-mode switching of coarse crushing (≤50mm), fine crushing (≤10mm) and sand making (≤3mm).

Intelligent adjustment: The hydraulic/spring system dynamically adjusts the roller spacing (1-20mm) to accurately control the particle size of the finished product.

When encountering hard or unbreakable objects, it will automatically separate and avoid to protect the core components of the equipment.

Environmental Protection and Energy Saving: fully enclosed structure + dust removal interface, dust spillage is reduced by 60%; unit energy consumption is reduced by 15-30% compared with impact crusher.

Wear-Resistant and Durable: The hardness of the roller skin is above HRC60, the service life is extended by 3-5 times, and the maintenance cycle exceeds 3000 hours.

FAQ's

Frequently Asked Questions

What products does your manufacturing company produce?

We provide a wide range of machinery, including briquette machines, mixers, dryers, and more, designed for various industrial applications.

What is the typical lead time for product delivery?

Lead times vary depending on the machine and customization options. Please contact us for specific timelines related to your order.

What materials can your briquette machines process?

Our briquette machines can process a variety of materials, including biomass, charcoal, and other organic waste products.

What are the energy requirements for your machines?

Each machine has specific energy requirements, which can be provided upon request. We aim to design energy-efficient solutions.

Request A Quote

Roller Crusher

Processing capacity: 1-50 tons/hour

Application: Suitable for continuous processing of medium and high hardness materials with compressive strength ≤160MPa, such as coal gangue, anthracite, charcoal slag, river pebbles, granite, etc.; widely used in raw material processing processes in sand and gravel aggregate production lines, briquette production lines, and charcoal ball production lines.

Features:

- Adjustable finished product particle size: adjustable range of discharging particle size 0.5-40mm;

- Strong adaptability, suitable for coal gangue containing moisture, charcoal slag crushing process;

- No screen bottom structure, no material blockage, suitable for long-term continuous production and processing technology;

- Long life, core wear-resistant roller, roller skin hardness reaches HRC60 or above, maintenance cycle up to several years;

- Less dust, no pollution: low crushing noise, less dust, environmentally friendly and clean.

- PDF DOWNLOAD