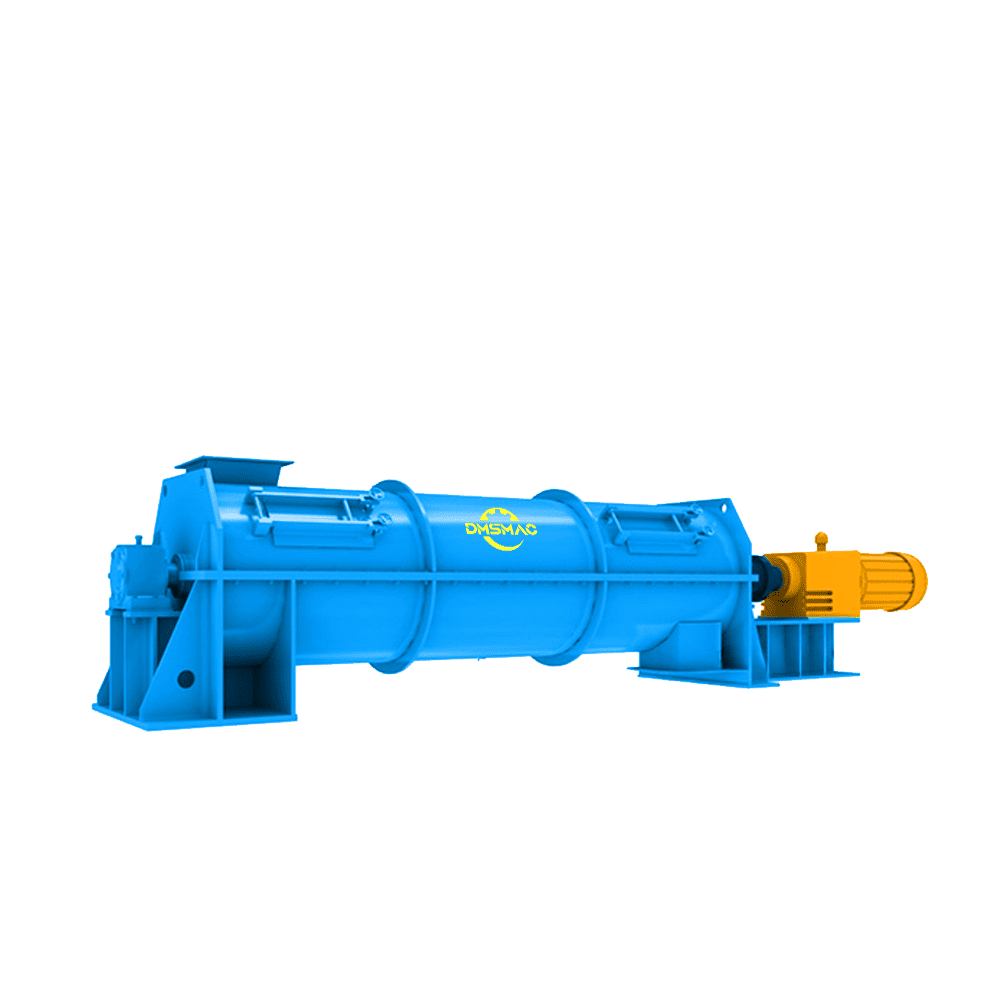

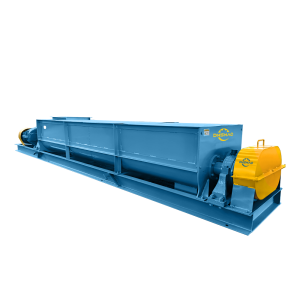

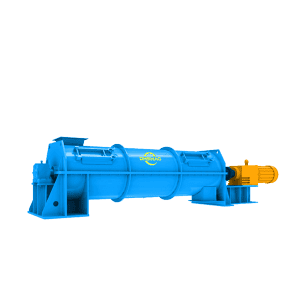

Twin Shaft Mixe-Batch Type

Processing Capacity: 5-200 tons/hour;

Application: production lines with continuous large output; mixing of granules or powders with a particle size greater than 10μm, and mixing with a small amount of water or binder; widely used in metallurgical dust removal, sludge recycling and steel pellets, such as laterite nickel ore, iron ore concentrate, magnesium oxide powder, bauxite powder, etc.

Features:

- Suitable for 24-hour/30-day long time, continuous and uninterrupted production;

- The mixing uniformity is as high as 95%;

- It has a disintegration function, high efficiency and large output;

- It has a compact structure, occupies a small space, and is easy and convenient to connect to the production line;

- It has a fully enclosed structure design, no dust, and a high degree of automation;

- PDF DOWNLOAD

The horizontal continuous mixer is a mixing equipment with a horizontal cylinder design. It realizes uninterrupted operation through continuous feeding and discharging. It is suitable for homogenization of materials such as powders, particles or semi-fluids;

Mixing principle:

It combines the three mixing principles of bulk mixing, convection mixing and shear mixing into one machine; the general product is driven by the motor through the hard tooth surface reducer, and then through the gear coupling (or hydraulic coupling) to drive the mixing rotor to rotate at a certain speed. The mixing rotor is fixed with a special geometric shape and high wear-resistant mixing tool. When the mixing tool rotates, the material is mixed in the cylinder and can be discharged continuously. The material moves forward and backward in the container to achieve the mixing purpose.

Advantages and Characteristics:

Overcome the opposite segregation effect of a single diffusion mixing mechanism to ensure a high degree of uniformity, thereby achieving the required degree of mixing, which can reach 95%, that is, the coefficient of variation V is not greater than 5-15%;

1. Drawing on advanced technologies from other regions, the mixing principle is mainly based on strong convection and shearing, with a high degree of mixing;

2. Horizontal structure, continuous mixing, to ensure the continuity of the production line;

3. It has both a breaking function, high efficiency and high output;

4. Compact structure, small footprint, simple and convenient connection with the production line;

5. Fully enclosed structure design, good on-site environment, high degree of automation;

6. Technology, the mixing tool has a clever structure, easy replacement and easy maintenance;

FAQ's

Frequently Asked Questions

What products does your manufacturing company produce?

We provide a wide range of machinery, including briquette machines, mixers, dryers, and more, designed for various industrial applications.

What is the typical lead time for product delivery?

Lead times vary depending on the machine and customization options. Please contact us for specific timelines related to your order.

What materials can your briquette machines process?

Our briquette machines can process a variety of materials, including biomass, charcoal, and other organic waste products.

What are the energy requirements for your machines?

Each machine has specific energy requirements, which can be provided upon request. We aim to design energy-efficient solutions.

Request A Quote

Twin Shaft Mixe-Batch Type

Processing Capacity: 5-200 tons/hour;

Application: production lines with continuous large output; mixing of granules or powders with a particle size greater than 10μm, and mixing with a small amount of water or binder; widely used in metallurgical dust removal, sludge recycling and steel pellets, such as laterite nickel ore, iron ore concentrate, magnesium oxide powder, bauxite powder, etc.

Features:

- Suitable for 24-hour/30-day long time, continuous and uninterrupted production;

- The mixing uniformity is as high as 95%;

- It has a disintegration function, high efficiency and large output;

- It has a compact structure, occupies a small space, and is easy and convenient to connect to the production line;

- It has a fully enclosed structure design, no dust, and a high degree of automation;

- PDF DOWNLOAD