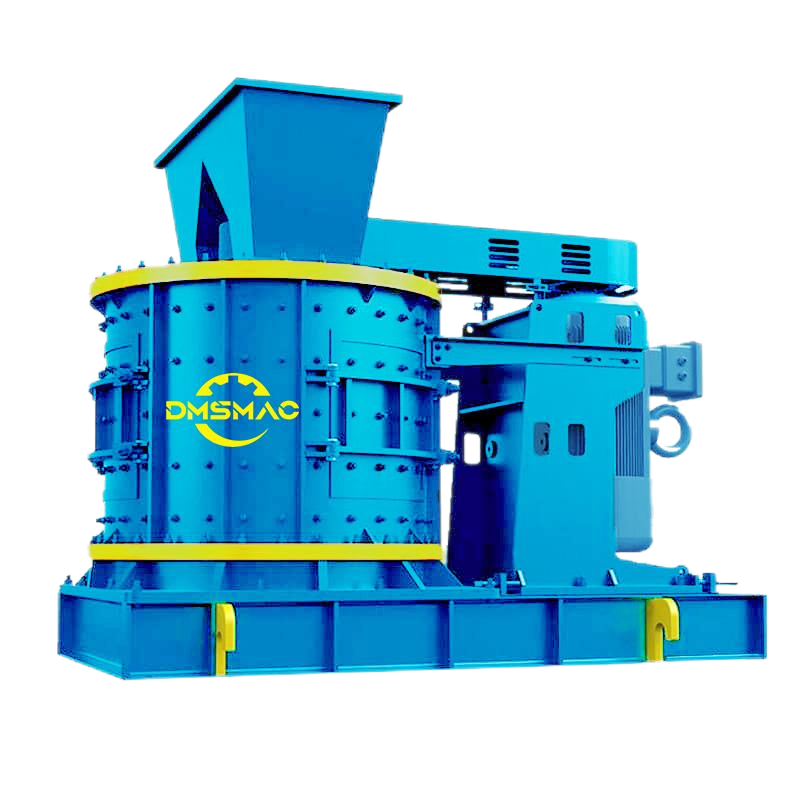

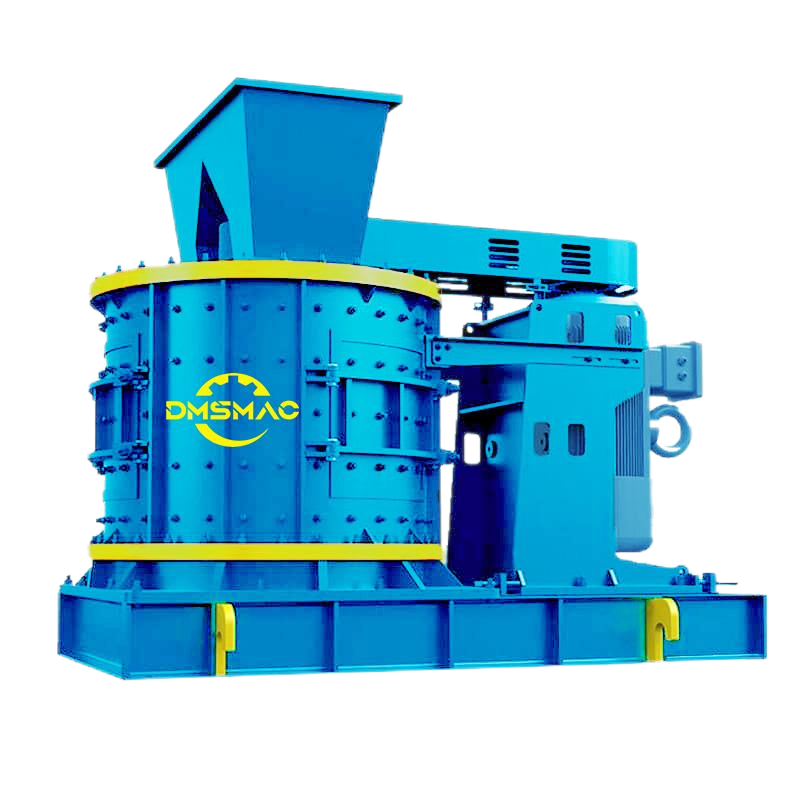

Vertical Hammer Crusher

Processing capacity: 1-140 tons/hour;

Application: widely used in the processing and crushing of medium-hard materials,such as glass, limestone, coal slag, anthracite, and coal gangue ; Crushing particle size can be less than 5mm; different layers and numbers of hammers can be installed according to needs to control the discharge particle size;

Features:

- No screen bottom design, suitable for materials with less moisture content;

- High crushing ratio 15-30, the finished product particle size can be less than 5mm;

- Low energy consumption, compared with the same type of hammer crusher with the same output, the energy consumption is 20%-35% lower;

- Low price, low operation and maintenance cost;

- PDF DOWNLOAD

What is a Vertical Hammer Crusher?

Vertical Hammer Crusher is a highly efficient and multi-purpose medium-hard material crushing equipment, which adopts a vertical shaft structure design and integrates the dual functions of impact crushing and hammer crushing. Its core components include a high-speed rotating vertical shaft rotor assembly, a multi-layer impact liner and a wear-resistant hammer head. It is suitable for materials such as glass, limestone, coal slag, anthracite, and coal gangue. It is widely used in sand and gravel aggregate production, metallurgical mining fine crushing, cement clinker processing and solid waste recycling. The equipment adopts a screen-free design with a crushing ratio of up to 15-30, combining low energy consumption (20%-35% energy saving compared to traditional equipment) and low maintenance cost advantages. The modular structure supports rapid replacement of wearing parts, and the special sealing technology can handle high-humidity (viscous) or high-temperature (≤200℃) materials to avoid blockage and dust spillage, meet environmentally friendly production requirements, and is an ideal crushing solution for building materials, metallurgy, energy and other industries.

How does a Vertical Hammer Crusher work?

The Vertical Hammer Crusher achieves material crushing through the high-speed centrifugal motion of the vertical shaft rotor. The motor drives the vertical shaft assembly (speed 800-1500r/min) to drive the circumferentially distributed hammers to rotate. After the material falls vertically into the crushing chamber from the top feed port, it is first strongly impacted by the high-speed rotating hammers to produce the initial crushing; then the material is thrown to the surrounding impact linings under the action of centrifugal force, and violently collides, squeezes and grinds with the multi-layer annular impact tooth plates (laminated crushing), forming a secondary crushing effect. During the crushing process, the material continues to be refined under the triple effects of hammer impact, impact plate extrusion and self-collision between materials, and is finally discharged through the bottom discharge port. Particle size adjustment can be achieved by adjusting the rotor speed or the gap between the impact linings, as well as the number of hammers. The non-screen bar structure avoids clogging of wet and sticky materials. The specially designed eddy current crushing chamber prolongs the material residence time and improves the crushing efficiency. The whole machine adopts a closed structure, combined with a dust removal device to ensure low dust operation and meet industrial environmental protection standards.

What are the wearing parts of the vertical hammer crusher?

- Hammer head;

- Liner plate;

- Bearing;

Note:

The selection of crushing equipment needs to be accurately selected according to the hardness and particle size of the raw materials, the particle size and output of the output, and the moisture content of the materials. Please consult the engineer in detail to obtain an accurate quotation.

FAQ's

Frequently Asked Questions

What products does your manufacturing company produce?

We provide a wide range of machinery, including briquette machines, mixers, dryers, and more, designed for various industrial applications.

What is the typical lead time for product delivery?

Lead times vary depending on the machine and customization options. Please contact us for specific timelines related to your order.

What materials can your briquette machines process?

Our briquette machines can process a variety of materials, including biomass, charcoal, and other organic waste products.

What are the energy requirements for your machines?

Each machine has specific energy requirements, which can be provided upon request. We aim to design energy-efficient solutions.

Request A Quote

Vertical Hammer Crusher

Processing capacity: 1-140 tons/hour;

Application: widely used in the processing and crushing of medium-hard materials,such as glass, limestone, coal slag, anthracite, and coal gangue ; Crushing particle size can be less than 5mm; different layers and numbers of hammers can be installed according to needs to control the discharge particle size;

Features:

- No screen bottom design, suitable for materials with less moisture content;

- High crushing ratio 15-30, the finished product particle size can be less than 5mm;

- Low energy consumption, compared with the same type of hammer crusher with the same output, the energy consumption is 20%-35% lower;

- Low price, low operation and maintenance cost;

- PDF DOWNLOAD