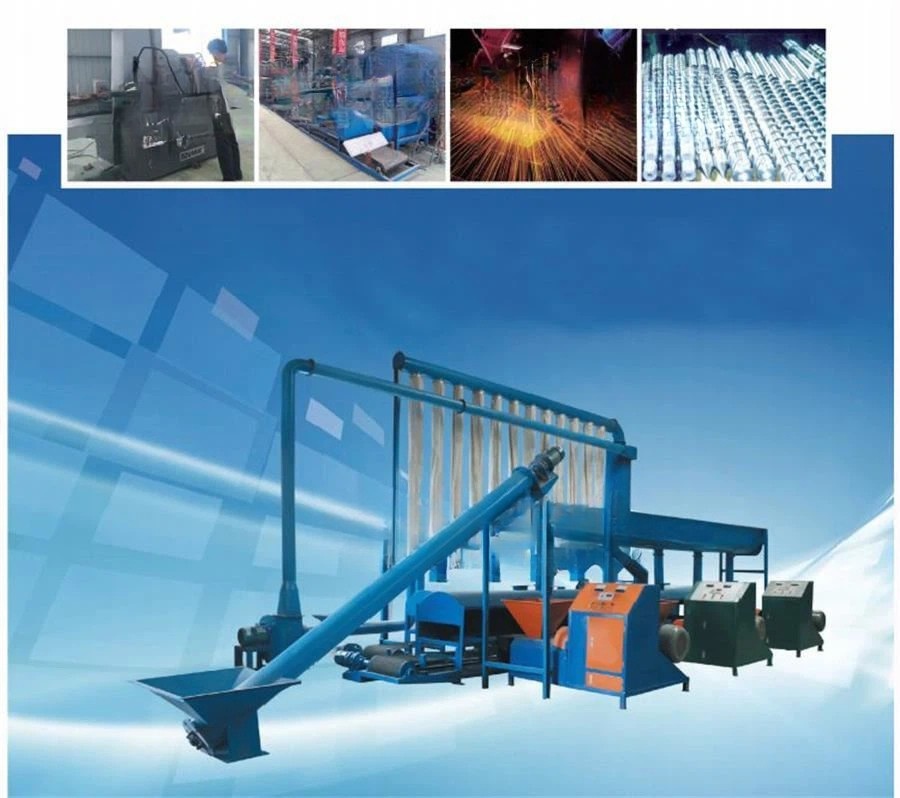

Ø Description Of Bamboo Wood Sawdust Charcoal Briquette Making Machine:

Briquette making machine will make the sawdust, straw (corn straw, soybean straw, sorghum straw, cotton stalk, rape straw, peanut, sunflower stalk), rice husk, straw, shrub, bamboo head, tobacco, bagasse and so on (length less than 5mm, diameter less than 3mm), which are high in the condition of without any binder. In the process of high temperature and high pressure, the solid bar is extruded into the center hole.

The machine has advantages of high density, small size, good flammability and can replace firewood and coal. Most of the general products are in the shape of four or six angles cylinder with 48, 50 and 80 mm outer diameter and 15-20 mm aperture. The utility model can also be made into spherical, granular and honeycomb briquette.

Ø The 10 Problems You May Encounter And Solutions During The Use:

You may encounter the following problems during the use of the stick making machine, I list it and solution here:

1. Reasons why the power indicator light of the console is not on:

a. Connect the power; b. Replace the fuse; c. The indicator light is broken.

Solution:

a. Connect the power;

b. Replace the fuse;

c. Replace the light bulb.

2. Reasons why the motor of the rod making machine does not start:

a. The control button of the briquette making machine is damaged; b. The phase is missing; c. The voltage and frequency do not match.

Solution:

a. Replace the control button;

b. Connect the power cord;

c. Check the voltage and frequency.

3. The reason why the heating temperature rises slowly and does not reach 350 degrees:

a. The power supply voltage of the briquette making machine is low; b. The resistance heating ring of the briquette making machine is damaged; c. The model of the briquette making machine is wrong when replacing the heating coil wire.

Solution:

a. Check the voltage of the briquette making machine;

b. Replace the resistance heating ring of the machine;

c. Replace the wire of the briquette making machine as required.

4. Reasons for the solid core of the briquette:

a. The tip of the propeller is deformed and bent; b. The tip of the propeller is not smooth.

Solution: a. Correct the coaxiality of the tip of the propeller; b. Polish the tip of the propeller.

5. Reasons why the briquette is not formed:

a. Cooling treatment can be done, remember not to cool down too fast.

b. Repair the propeller as required.

c. The moisture content of raw materials is higher than 11%.

6. Reasons for no briquettes and return of materials:

a. The temperature is not enough; b. The pressure of the propeller is too large.

Solution:

a. Continue to increase the temperature;

b. Increase the thread lift angle and reduce the pressure.

7. Reasons for briquette many cracks:

a. High temperature; b. The propeller is not repaired; c. The mold is worn; d. The raw material lignin is low.

Solution:

a. Cool down temperature slowly, not too fast;

b. Reduce the thread angle and increase the thruster pressure;

c. Replace or repair;

d. Add raw materials with heavier specific gravity, or replace the raw materials after fermentation use.

8. Longitudinal cracks: a. The temperature is too high. b. The inclination of the propeller is too large; c. The mold is damaged.

Solution:

a. Lower the temperature;

b. Repair the inclination as perpendicular to the axis as possible;

c. Replace or repair.

9. Reasons for the explode of the briquette making machine:

a. The material is too wet; b. The briquette core is blocked. Improper temperature control, excessive raw material moisture, wear of the propeller, improper shaft tip, blockage of the exhaust hole, too large or too small of the propeller head to the screw, serious wear of the forming cylinder, etc. In this case, the above reasons should be compared one by one, and adjustments should be made accordingly after the reasons are identified.

Solution: a. Adjust the drying temperature and dry the material; b. Replace or repair; c. Mix raw materials with heavier specific gravity, or replace the raw materials or wait for the raw materials to ferment for 3-5 days before use.

10. Reasons for sometimes can do briquette and sometimes can’t do briquette:

a. The power of the heating ring is not enough. b. The material is not dry enough; c. The temperature of the raw material is uneven.

Solution:

a. Replace the high-power heating ring, or increase the drying temperature;

b. Increase the drying temperature of the raw materials;

c. Use or adopt after materials cooling.

d, adjust the propeller ratio.

Ø 2021 A New Generation Of Frequency Conversion Energy-Saving Rear Dismantling And Rear Adjusting Propeller Shaft Rod Making Machine:

Tne New Generation Briquetting Machine ,The propeller of the patented equipment has a unique design, and the speed and density of the rod can be adjusted forward and backward at will. Whether it is wood shavings, bamboo chips, or various wood bran or straw, peanut shells and other raw materials, the propeller can automatically and evenly unload the material when stirred. The turbo reducer is equipped with a 11-15kw electric motor, which is energy-saving, more powerful in frequency conversion rod making pressure, and higher in output (400-500 kilograms per hour).

Features: Energy saving, rear dismantling and rear adjustment of the propeller, frequency conversion, large head, large bearing, fast rod making speed, high salary rod density, high work efficiency, long service life and wide application range.