About Us

Briquette Machinery & Mesh Belt Dryer Manufacturer

Henan Damas Machinery Co., Ltd focused on good quality briquette machine R&D for over 20 years in China. We start from coal briquetting machine in local market, but now we are considered to be the leader manufacturer in briquette machine industry in China.

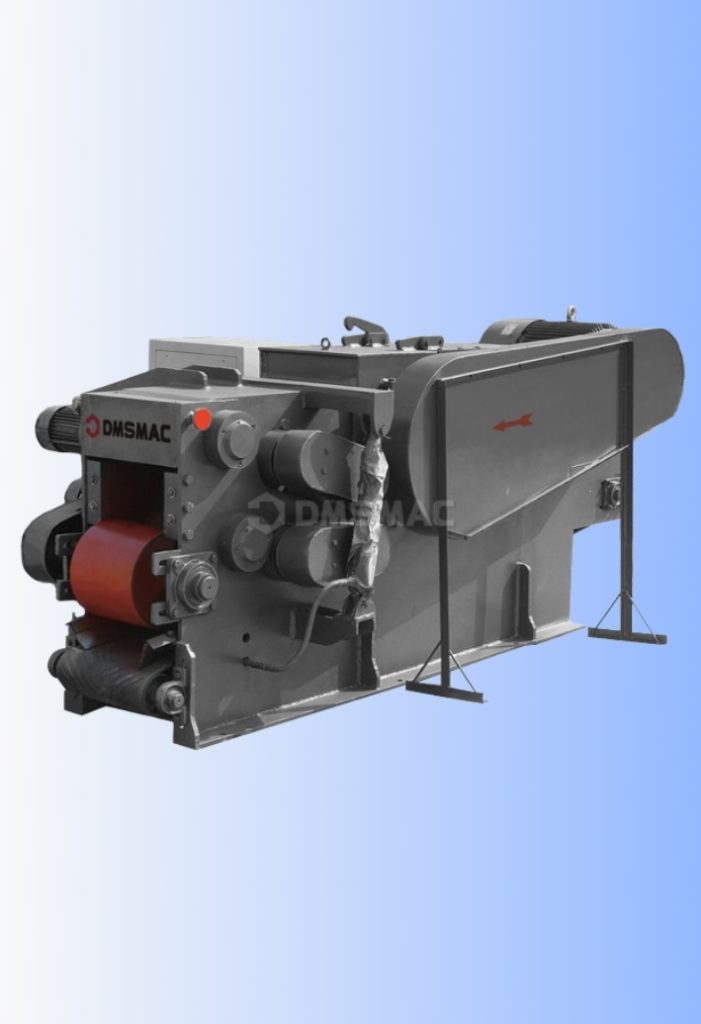

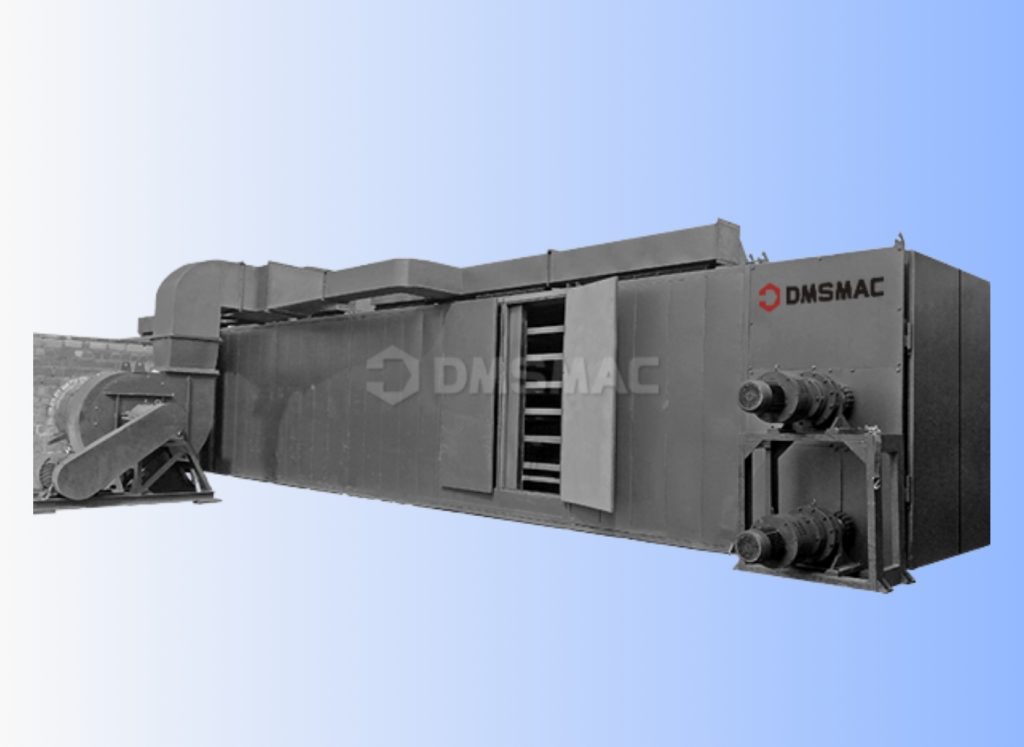

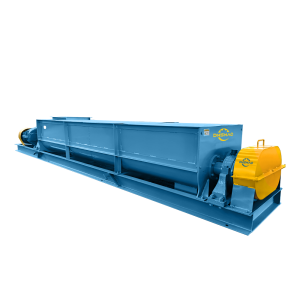

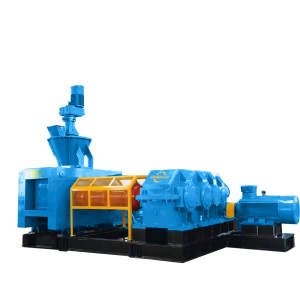

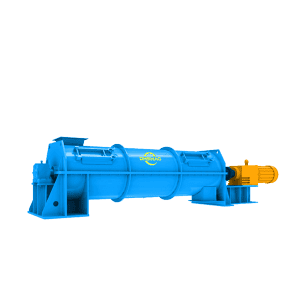

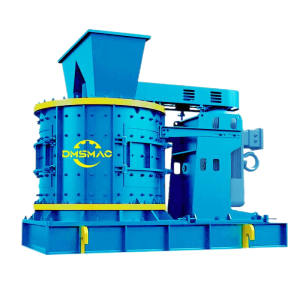

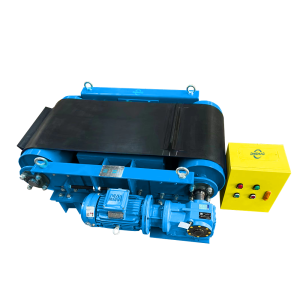

Today, Damas BRIQUETTE MACHINE has been one of the best brand of quality coal/charcoal briquette and biomass briquette production line, such as coal briquette press, biomass briquette press, pellet mill, screw briquette press, sawdust pellet machine, especially for sawdust air flow dryer, charcoal / coal briquettes belt dryer and so on.

About Us

Briquette Machinery & Mesh Belt Dryer Manufacturer

Henan DAMAS Machinery Co.,Ltd., known as the Professional Briquette Machinery and Briquettes Dryer--Belt Dryer Manufacturer,integrating R&D, manufactuer,distribution, and production together.

20+

Years of Industrial Experience

Owning professional engineer and staff and professional punch,KHK,jumbo,boring mill machine,etc processing machinery, we are considered to be the leader in the briquette machine manufacturer industry in Henan.

Products

Products

FAQ's

Frequently Asked Questions

What products does your manufacturing company produce?

We provide a wide range of machinery, including briquette machines, mixers, dryers, and more, designed for various industrial applications.

What is the typical lead time for product delivery?

Lead times vary depending on the machine and customization options. Please contact us for specific timelines related to your order.

What materials can your briquette machines process?

Our briquette machines can process a variety of materials, including biomass, charcoal, and other organic waste products.

What are the energy requirements for your machines?

Each machine has specific energy requirements, which can be provided upon request. We aim to design energy-efficient solutions.

Request A Quote

LAST News

Support Services

Expert Consultation Services

Our consultation services are designed to help you select the best machinery for your specific needs. We provide insights and recommendations to make informed decisions.

Professional Installation

Our skilled technicians ensure that your machinery is installed correctly and efficiently, minimizing downtime and maximizing productivity from the start.

Reliable Maintenance Support

Regular maintenance is crucial for optimal performance. Our team provides comprehensive maintenance services to keep your equipment in top condition.

Quality of service that no one can match

Manufacturing Company offers an unparalleled quality of service that is unmatched by any other in the industry. With our extensive experience and dedication to excellence, we strive to deliver exceptional manufacturing solutions that meet and exceed our clients' expectations. Our team of skilled professionals utilizes state-of-the-art technology and the latest industry practices to ensure top-notch results we pride ourselves on our attention to detail.

Isn’t it time to stop leaving money on the floor?

Talk with a coal briquetting expert about how you can add revenue to your business.