Auxiliary Equipment

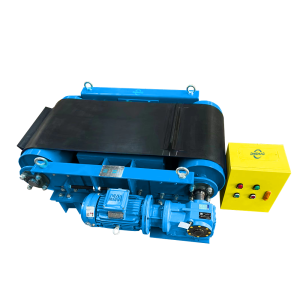

Auxiliary equipment is the key support for efficient and continuous operation of production line. Conveyor is the key to achieving seamless and continuous flow of materials. Iron removers accurately intercept metal impurities to protect equipment safety. Buffer bins adjust production capacity fluctuations to ensure continuous production. Packaging machines ensure standardized product output. Dust collectors optimize the environment and meet environmental protection requirements. These equipment complement each other and work together in improving efficiency, reducing energy consumption, and controlling costs, helping production lines build a stable, intelligent, and sustainable production system, providing core guarantees for the continuous, efficient, and continuous operation of production lines.

Auxiliary Equipment

Product Categories

Briquette Production Line

Roller Briquette Machine

Dryer system

Heat Source System

Mixer System

Crusher System

Auxiliary Equipment

Recommended Cases

The Briquettes Adhesive Secret, You Don’t Know

The adhesive, there are m

Influence Of Pretreatment Process Of Ball Press Binder

Influence of pretreatment

5 tons per hour fluorite powder briquette press production line

5 tons per hour fluorite

20 Tph Coal Briquettes Plant In Heibei Province

Raw Materials : coal Mois

FAQ's

Frequently Asked Questions

What products does your manufacturing company produce?

We provide a wide range of machinery, including briquette machines, mixers, dryers, and more, designed for various industrial applications.

What is the typical lead time for product delivery?

Lead times vary depending on the machine and customization options. Please contact us for specific timelines related to your order.

What materials can your briquette machines process?

Our briquette machines can process a variety of materials, including biomass, charcoal, and other organic waste products.

What are the energy requirements for your machines?

Each machine has specific energy requirements, which can be provided upon request. We aim to design energy-efficient solutions.