●Raw materials:CHARCOal BRIQUETTES;

●Production capacity:20-30t/d per set;

●Raw materials moisture:36% inlet to ≦8% outlet;

●Raw materials size:45*45*35mm;

●Final briquette size: square.

Coal briquettes are widely accepted by all over world because of easy package and less pollution during delivery process. Most importantly, some of coal dust can be recycle by press into coal briquettes for industry boiler and fireplace in home to be fuel. But how to press the coal into briquettes, and how about the coal briquetting technology and where to get the briquette making process to know well who can supply briquette production process? Especially for the briquetting plant equipment and briquette plant price and briquette plants machine, who can supply the quotation? DMSMAC BRIQUETTE MACHINERY, professional at briquetting plant machine manufacturer and you can get best briquetting pant price and complete all briquetting technology support!

1, Rotary dryer, applicable for raw materials coal/sludge drying process, because of 15%-20% moisture content during the coal briquette press process. Detailed information please check the our products of rotary dryer;

2, Hammer crusher, known as coal crusher also, we request the feed size for coal briquette machine shall be less than 3mm, and big size raw materials will block the rollers or speed up the wearing of rollers. Meanwhile, the small size of coal dust can mixed with water and binders well, which will help press the good quality briquettes;

3, Binders Feeder Device, recently, powder binders are widely used such as starch. Binders feeder are mainly designing for powder binders, the screw conveyor are assembled to control the speed of binders feeding by adjustable of screw conveyor speed.

4,Mixer, two kinds of mixer for coal briquettes plant are recommended for two kinds of different process, depends on customers request and preference. Coal dust and water & binders will be mixed evenly in mixer for next process pressing.

First: Double Shaft Mixer, which is more easy automatic work in production line;

Second: Wheel Mill Mixer, need two workers control the binders and water; We can design the automatic feeding device also by PLC set and control;

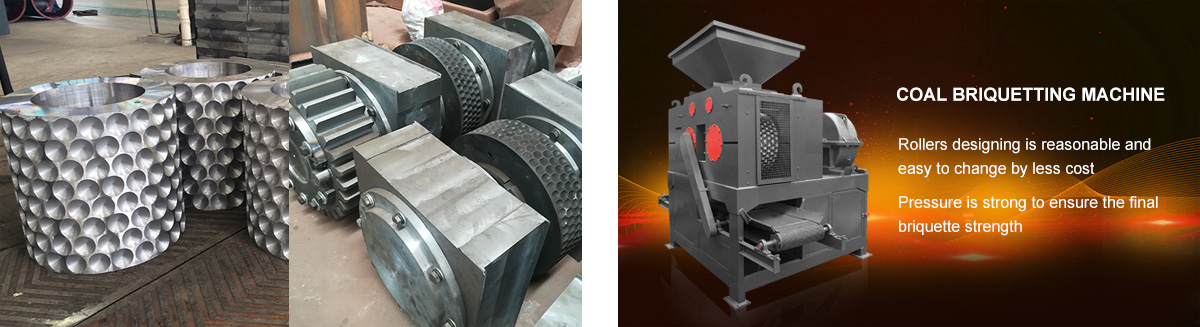

5, Briquette Press: coal briquette press machine,press the coal dust mixed with water and binders well into briquettes by two rollers driven by motor through reducer. One of our key technology is the connection rollers, more easy to do maintenance and less cost, detailed connection information kindly check the news-solution advantage of connection rollers.

6, Briquettes Dryer: Recently, vertical dryer, tower dryer, mesh belt dryer,chain plate dryer are the main dryer in market.

Coal briquettes are widely accepted by all over world because of easy package and less pollution during delivery process. Most importantly, some of coal dust can be recycle by press into coal briquettes for industry boiler and fireplace in home to be fuel. But how to press the coal into briquettes, and how about the coal briquetting technology and where to get the briquette making process to know well who can supply briquette production process? Especially for the briquetting plant equipment and briquette plant price and briquette plants machine, who can supply the quotation? DMSMAC BRIQUETTE MACHINERY, professional at briquetting plant machine manufacturer and you can get best briquetting pant price and complete all briquetting technology support!

Get catalogs & price!