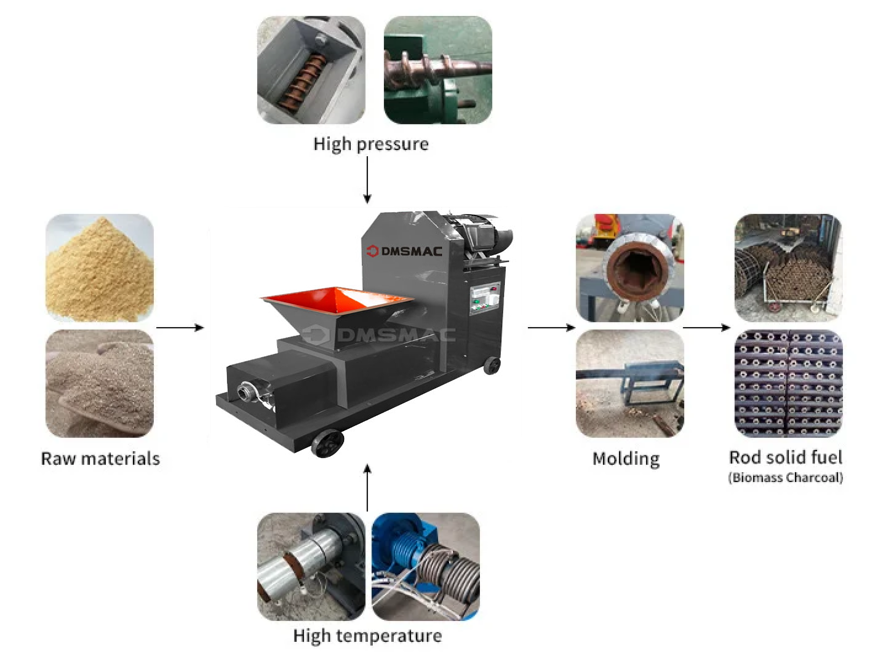

Application:sawdust, straw (corn stalks, large soybean straw, sorghum, cotton stalk, rape straw, peanut vine, sunflower stalk), rice husk, grass, shrubs, branches, wood cut head, bamboo shavings, bagasse and other raw materials after extrusion screw propeller and rods made of high temperature sleeve and other biomass materials from farm.

Capacity:100-500kgs per hour.

Material Requirements:material size ≦3-5mm, moisture content ≦12%.

▶Product Advantage:

★★★ No need to dismantle parts complicatly.

★★★ Remove and adjust the propeller easily.

★★★ No need to preheat repeatedly.

★★★ The propeller can automatically and evenly unload the material without returning or picking the material.

★★★ Adjust the briquette making speed and density at any time.

★★★ High performance, low loss, high productivity.

▶Working Principle:

The crushed (size less than 5mm) and dried (moisture less than 12%) biomass materials enter the hopper,and push the material to the forming cylinder through the action of the screw propeller; at this time, the angle between the propeller and the forming cylinder is a huge pressure is formed; and under the high temperature of the heating ring, the material will decompose lignin; the material will shape the material under the combined action of these factors, and finally form briquette.

▶Technical Parameters:

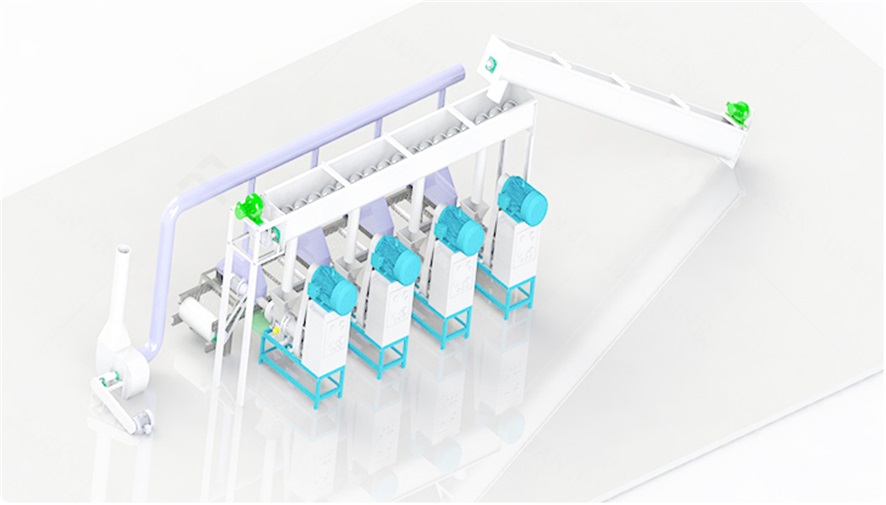

▶Production Line:

the following line is based on sawdust or rice husk,briquette output capacity: 1t/h.if you use other material,the produciton line can be adujusted.

Get catalogs & price!