Application:briquetting for various powders or fines or dust, such as coal powder, iron powder, coking coal, aluminum powder, iron filings, iron oxide scale, carbon powder,DRI,slag, gypsum, tailings, sludge, kaolin, activated carbon, coke powder, sponge iron,clays,metallurgical ore powder, manganese ore powder, steel slag, slag, metallurgical waste, silicon-manganese alloy and other powders and etc.

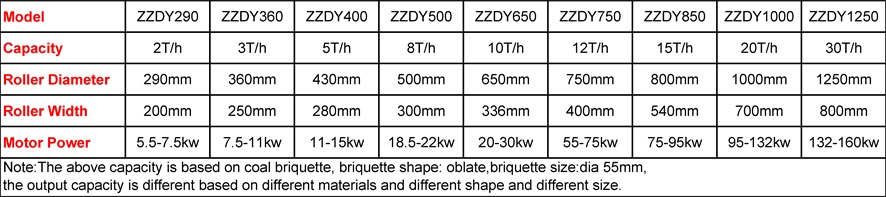

Capacity: 1-60tons per hour.

Material Requirements: material fineness ≦3-5mm, moisture content 7-15%.

Roll Material: 9Cr2Mo or 9Cr18 or GCr15

▶Product Advantage:

---Hydraulic System Option

---Horizontal and Vertical Feed for Screw or Gravity Feed Options

---Pocket Adjustment Design to Make Sure Getting Beautiful Final Briquettes

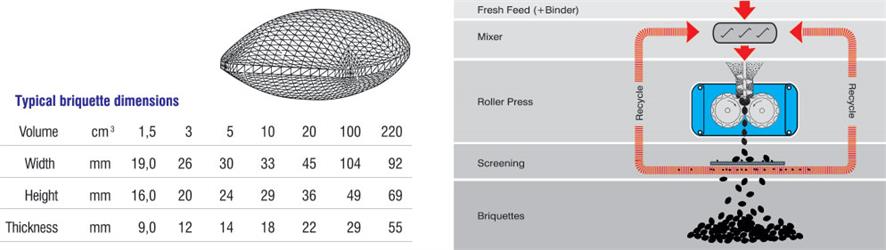

---Customized Sizes and Shapes for Briquettes

---Variable Speed Roll and Screw Feeder Drives to Maximize Product Quality

---Rolls and Feed Screws Available In Wear and Corrosion-Resistant Alloys

---Designed For Easy Maintenance

---Solid Oil Filled Bearings Option

▶Working Principle:

The material to be briquetted is introduced into the space above two counter-rotating rollers via feeder system. On passing through the roller gap, the material is compacted and formed into briquettes of uniform size and shape. For briquetting at feed material , it may be necessary to add binders to improve the briquette-forming characteristics.

▶Technical Parameters:

▶Engineering Case:

Get catalogs & price!