Coal Briquettes Plant standard production line equipment list:

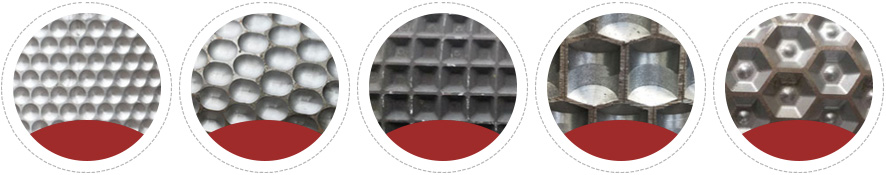

Crusher, raw materials grinding device;

Mixer, mix coal dust with binders as request rate;

Briquettes press machine, press the mixed coal dust into briquettes as designing shape and size;

Final Briquette Dryer, drying the wet briquettes to suitable for storage and package.

The reasonable designing of the production can save much budget and space of the production line.

Applicable of coal briquettes:

Metallurgical industry. The fine of non-ferrous metals and ferrous metals can be briquette and re-smelting, such as laterite nickel ore, alum ore, manganese ore, furnace dust, steel slag, mineral waste residue, carbon black, copper powder, magnesium, alumina, iron ore concentrate, manganese ore, etc.

Coal fuel briquette making. Making coal briquettes from coal fines, coke powder, slime, and midding coal, etc, the briquettes are used in industrial boilers and civil furnaces.

Thermal power plant. Use the desulfurization gypsum making briquette as cement retarder.

Chemical fertilizer industry. using coal dust to make briquette, instead of using lump coal, saving energy cost.

Building materials industry. The ceramic factory, glass factory and the coal- gas generator, using coal fine briquette replace the lump coal for energy cost saving.

Refractory industry. Making refractory briquette.

Every kind of industry with powder material which should be briquette and then used in the kiln.

Coal Briqutts Plant Standard Process

A standard briquettes process for roller briquette machine plant as following:

Silo ⇒ Crusher ⇒ Buffer Bin ⇒ Mixer ⇒ Silo ⇒ Briquette Machine ⇒ Final Briquettes Dryer

Silo: Silo is used to store the material for a smooth feeding for the next step;

Crusher:Feeding size request to less than 3-5mm, Crusher is used to grind the raw materials into dust/ash to get proper size material to make well binder mixing result; Traditional, there is vertical hammer crusher and double stage hammer crusher used for this grinding purpose.

Buffer Bin: buffer bin is used to store the grinding material for smooth feeding next step, which can be built at site by client or order from us;

Mixer: Main stage of the briquettes plant, mix the coal dust with binders evenly. A good binder mixed material will get a high strength briquette as well as the briquette shaping rate. The water (if needed) and binder will be added here; There is three different mixer for reference: double shaft mixer, wheel mill mixer and screw mixer also. Different type and capacity production, we will assemble the suitable mixer for the coal briquettes production line.

Final Briquettes Dryer: Considering the further package work or the storage or transport, dried briquettes will be hard enough for loading. Final briquettes need to be dried after press machine. You can choose latest chain plate dryer(advanced belt dryer) according to your budget and working shop size request; For super capacity output production line, more working unite can be considered also. There is affordable vertical type dryer widely used also, if there is space and time to dry briquettes, dryer can be replaced by sunshine or drying room.

Raw Material and Attention

Raw material can be processed: Coal dust like brown coal, lignite coal, lean coal, anthracite, peat, and the old brown coal, charcoal fines, coke dust/fines, peacoke, carbon black, carbon dust, clay, activated carbon, etc. The materials size and moisture requests before briquetting: In order to ensure the good quality and mechanical strength of the final product, special care should be taken to ensure that the granule size fed to the machine is maintained below 3mm, preferably in the range of 30-40% smaller than 1–2 mm, with no more than 10% over 2 mm.

DMSMAC Advantage:

1. Reasonable flow chart designing to save space and budget;

2. Quality machine option to be sure the stable&enough output;

3. Precise binders quantity control to save operation cost;

4. Rich experince technical site installation and trainning work carried out;

5. Twenty-four seven service on line support.

Coal Briquettes Plant

--Dryer AssembledApplication: widely assembled for the output more than 5 tons briquettes plant.

Advantage: Continuous working 24/7; Less labor needed for complete plant;

Coal Briquettes Plant:

-- Drying by sunshine or drying room

Application: mini type plant with capacity less than 3 tons per hour.

Advantage: Less investment and space request; Easy operation by common technology workers .

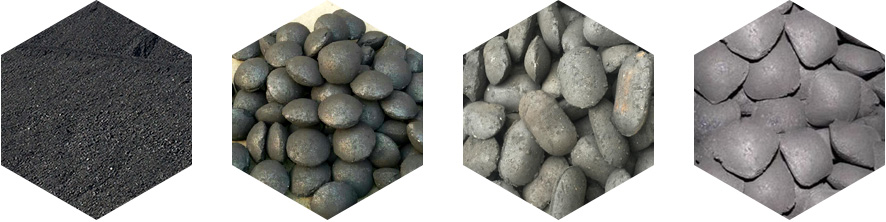

Shape: custom-made accepted, oblate, oval, pillow, square, and special shape designing.

Size: Changeable size 18mm-80mm, made according to clients requests.

Get catalogs & price!