high quality and reliable briquette combustion

equipment for industrial production

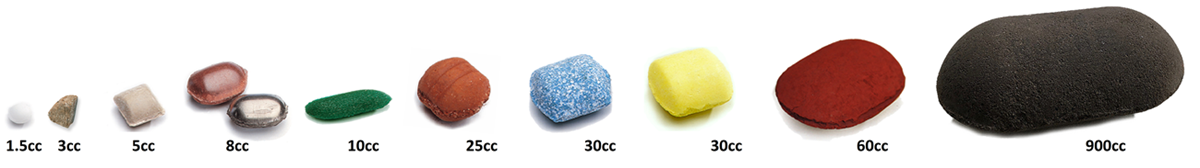

The briquetting process allows to reduce the volume of the powder by its densification to reach briquettes with a true density of about 5g/cm³.

The capacity of a briquetting line can range from 50 kg/h to 100 T/h.

The briquettes are obtained at low or high pressure (from 5 to 180 kN/cm) and can undergo mechanical or heat treatment depending on the characteristics of the treated material and the desired final product.

If the cohesive forces (particulate cohesion, valence forces, recrystallization, van Der Waals forces…) between the particles are low, a binder has to be used before agglomeration. The physical properties of the feed material, the end use of the briquettes and the cost of binder addition have to be taken into account before a selection is made. A large variety of (liquid or solid) binders is offered: starch, bentonite, bitumen, lime, cement, water, flour, lignosulphonates, molasses, polymer, resin, sodium silicate, fibers such as paper pulp, etc…

According to the material, the main stages of the briquetting process can be as follows:

♥ (if necessary a product preparation unit such as screening-crushing, drying, sieving).

♥ Dosing and mixing of product with binder.

♥ Briquetting unit.

♥ (if necessary a post treatment of the briquettes such as air or oven drying, curing, polymerization, maturation).

Briquetting Machine

Briquetting Machine

Briquetting Machine, known as Briquetting Press or Roller Press For Briquetting, Compaction and Grinding, widely used for various powders or fines or dust such as coal, coke,charcoal, iron,coking coal,aluminum, iron filings, iron oxide scale, carbon powder, slag, gypsum...

learn more > High Pressure Briquette Machine

High Pressure Briquette Machine

GY-S series high pressure briquette machine is for briquetting powder material without water or additive.Mainly used in metallurgical industry powder material molding and smelting,like lime powder,cryolite,aluminum oxide,magnesium,bauxite and nonferrous metal industry p...

learn more >Get catalogs & price!