Application:briquetting for various powders or fines or dust,more detailed see the below.

Capacity: 1-30tons per hour.

Material Requirements: material fineness ≦3mm

Roll Material: 9Cr2Mo or 9Cr18 or GCr15

▶Fields of Application

You will find in this page, examples of industrial applications using our briquetting technology.

Of course this list is not exhaustive and we hope that you will not hesitate to contact us in order to obtain more technical information about ways to process your product:

--Chemicals (sodium sulphate, sodium chloride, sodium formate, maleic anhydride, carbonates, sodium cyanide, potassium cyanide, iron sulphate, potassium bromide, ammonium bromide, boric acid, urea, precipitated silica, dimethyl terephthalate, polymers ...)

--Minerals (alumina, bauxite, lime, hydrated lime, burnt lime, dolomite, gypsum, china clay, magnesia, fluorspar, paint pigments, sulphur, fluorite, molybdenum oxide...)

--Gypsum from power station flue gas desulphurisation

--Fertilizers (potash)

--Minerals (aluminium, chromium, cobalt, copper, iron, iron ore, manganese, lead, zinc, nickel, hematite, lead ore...)

--Coal: production of briquettes for home or industrial heating (partial coke oven charge, briquettes treated to obtain formcoke, briquettes for gasification).

--Coal for production of activated carbon

--Lignite-brown coal, peat, etc...

--Charcoal

--By-products from steel mills and metallurgy

--Graphite, carbon black

--Clay, bentonite

--Detergents

--Steelworks waste materials and by-products (sludge, mill dust, sintering fines, mill scale, coke fines, flue dust...)

--Dried sewage sludge

--Silicon

--Aromatic powder

--Sugar

...

▶Product Advantage:

---With Hydraulic System,Effectively Extend The Service Life of the Roller

---Horizontal and Vertical Feed for Screw or Gravity Feed Options

---Pocket Adjustment Design to Make Sure Getting Beautiful Final Briquettes

---Customized Sizes and Shapes for Briquettes

---Variable Speed Roll and Screw Feeder Drives to Maximize Product Quality

---Rolls and Feed Screws Available In Wear and Corrosion-Resistant Alloys

---Designed For Easy Maintenance

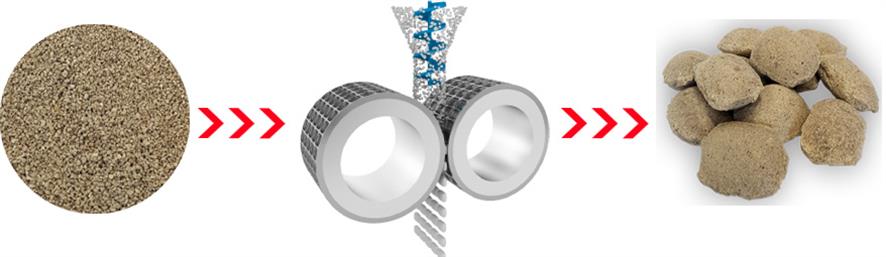

▶Working Principle:

The briquetting process allows the compression of volatile or voluminous powders between two rollers rotating in opposite directions in order to obtain a calibrated shape and size with higher densification. This densification step offers many possibilities regarding the use of the material and, in some cases, it can also be an essential condition for the continuation of the process.

Get catalogs & price!