Applicable:

Coal briquette machine, known as briquetting press machine or Roller Press also, is a kind of mechanical equipment which can be used for converting dust materials into briquettes through by high pressure roller press, which is mainly composed of motor, reducer, mainframe, belt conveyor, roller, Pressure system and electric control, etc.

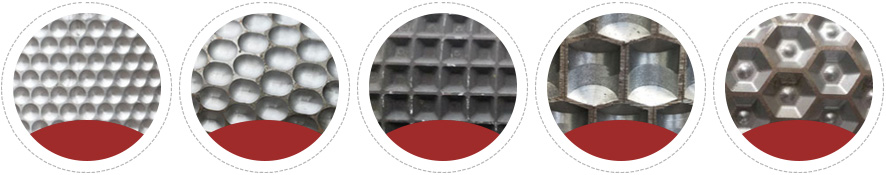

Working Principle: The material fall into the middle of two rollers by it’s own gravity effect , two roller surface evenly distributed roll socket of the same shape, two rollers’ speed is same and relative rotation , make the material into the socket and force compression, with the roller continue rotate, the briquettes take off on its surface tension and gravity.

Raw Material and Attention

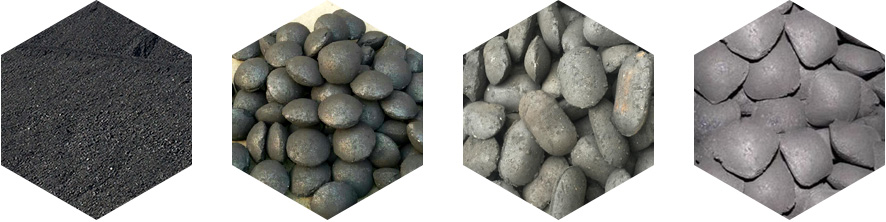

Raw material can be processed: Coal dust like brown coal, lignite coal, lean coal, anthracite, peat, and the old brown coal, charcoal fines, coke dust/fines, peacoke, carbon black, carbon dust, clay, activated carbon, etc. The materials size and moisture requests before briquetting: In order to ensure the good quality and mechanical strength of the final product, special care should be taken to ensure that the granule size fed to the machine is maintained below 3mm, preferably in the range of 30-40% smaller than 1–2 mm, with no more than 10% over 2 mm.

Features:

1. Big forming pressure and adjustable revolution of the main engine.

2. Simple structure and convenient operation.

3. High Balling rate and little power consumption.

4. Compact structure which is easy to repair and debug.

5. Uniform product size and reliable product quality

Application: No need to mix with binders, Moisture content is over 15% , Coal dust size is over 3-5mm.

Advantage: Less investment, and less power consumption, and high output capacity.

Application: no need to mix with binders, moisture content less than 10%, Coal dust less than 2mm.

Advantage: Hydraulic system to supply the powerful press, meanwhile to protect the rollers surface from hard metal.

Shape: custom-made accepted, oblate, oval, pillow, square, and special shape designing.

Size: Changeable size 18mm-80mm, made according to clients requests.

Get catalogs & price!