Advantage of Double Shaft Mixer

1, Sturdy and durable due to the steel alloy balde and solid axle

2, Continuous working by 24/7

3, Speed regular as output request

4, Powerful enough for large output as request, gear box and motor driven system

5, Dust free due to the cover assembled

6, Can be heating by steam at special cold area

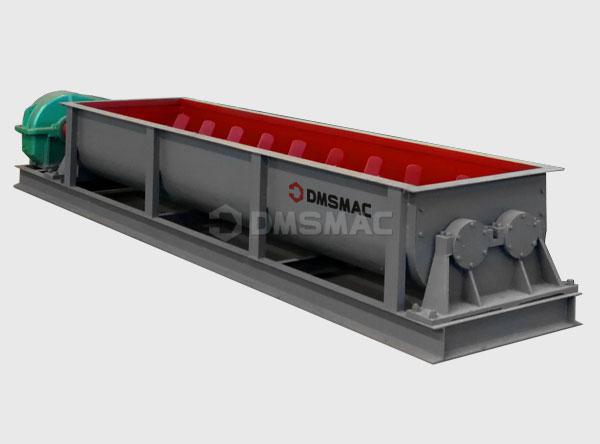

Double Shaft Mixer

Double shaft mixer is used in coal processing or brick making industry. Its maintenance is simple, stable,high efficiency and energy saving. It adopts double shaft propeller crossing type, in the process, cutting, pulling and stirring atone time to make material fully be mixed. Propeller angle can be adjusted to tally with required evenness. Due to it’s continuous working performance, it is more suitable for line production.

Working Principle

The double shaft is driven by motor and gear box through gear, the blade with angle is driven following shaft circular motion. The materails are lifted to move forward following the blade rotary moving. The blade angle can be set as request to set the mixing time and speed. Normally, many sets mixer will be set together to work to guarantee the mixing time and quality.

Technical Data

Model | Capacity (t/h) | Chute length (mm) | Propeller Diameter (mm) | Power (kw) | Stirring type | Spraying type |

ZZDM3000 | 7-10 | 3-4 | 350 | 11-15 | Double shaft propeller stirring | Straight +Spraying Nozzole |

ZZDM4000 | 10-18 | 3-4 | 450 | 15-22 | ||

ZZDM5000 | 15-25 | 3-5 | 550 | 22-37 | ||

ZZDM6000 | 22-32 | 3-5 | 650 | 37-45 | ||

Remarks | Capacity will be different based on various material specific gravity. above capacity based on industry coal fines. | |||||

Advantage of Double Shaft Mixer

1, Sturdy and durable due to the steel alloy balde and solid axle

2, Continuous working by 7*24h

3, Speed regular as output request

4, Powerful enough for large output as request, gear box and motor driven system

5, Dust free due to the cover assembled

6, Can be heating by steam at special cold area

Get catalogs & price!